Commercial, plus Residential Acoustic and Soundproofing Products

Visit www.CinemaShop.com,

or call toll free #866-243-1001 Mon-Fri 9 am to 5 pm central

Soundproof Walls

Home » Soundproof Rooms » Soundproof Walls

Soundproof Room Basics

It is important to plan ahead if you want to keep sound from getting out of a new room setting, as the process to isolate the room must be done as construction begins - it's best to install Sound Isolation Products before any wall framing has begun. While we can work with rooms with existing framing in place, there is a noticeable drop in performance in these situations. Please contact us, or call #866-243-1001 toll free regarding your room and we will be happy to work with you to find the best sound isolation solution for your setting. Improvements in Room Acoustics, however, are done after the room is completed with our Fabric Walls, Acoustic Panels, Seating Riser Bass Traps and 4" Acoustic Front Walls. Room Acoustics, or Room Tuning, which makes the room sound great, is quite a different process than Sound Isolation, which keeps sound in.

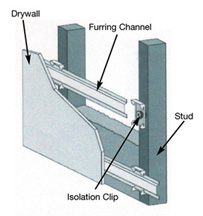

Framing Isolation - Resilient Sound Isolation Clips

The

first

issue involves wooden studs and the sound they transmit through your room’s

framing. Both the floor below the studs, as well as the wallboard attached

to it transmit sound through the studs, which are then transmitting

vibration to other room areas. If you deaden the studs, you will stop sound

from not only being sent to adjacent room areas, but also from travelling up

through the ceiling. Using our Resilient Sound Isolation Clips is a very

effective method of controlling sound travelling through walls, as well as

up through ceilings to stop it from travelling to rooms above.

The

first

issue involves wooden studs and the sound they transmit through your room’s

framing. Both the floor below the studs, as well as the wallboard attached

to it transmit sound through the studs, which are then transmitting

vibration to other room areas. If you deaden the studs, you will stop sound

from not only being sent to adjacent room areas, but also from travelling up

through the ceiling. Using our Resilient Sound Isolation Clips is a very

effective method of controlling sound travelling through walls, as well as

up through ceilings to stop it from travelling to rooms above.

Resilient Sound Isolation Clips provide 2 unique approach's to sound privacy that will prevent sound from noisy neighbors transmitting through your walls or floor/ceiling assemblies.

Experience with the Clips has recorded remarkable improvements of up to an additional 20 STC points on walls. The Clips are designed to retrofit and improve existing walls and ceilings has shown to improve existing walls by as much as 8-10 db. by actual field tests.

-

Resilient Sound Isolation Clip shall be 48 inches maximum on center. (horizontal)

Resilient Sound Isolation Clip shall be 48 inches maximum on center. (horizontal) - Fasten the Resilient Sound Isolation Clip to the substrate with a fastener approved for a minimum pull-out and sheer of 120 lbs.

- Ensure the internal metal ferrell is tight to the substrate. • Locate the first row of clips within 3 inches from the floor and within 6 inches from the ceiling.

- Snap in the drywall furring channel (hat track) into the clips (horizontal for walls).

- Place 1/4” (minimum) shim on floor to fully support the gypsum board.

- Install the gypsum board from the bottom up leaving a 1/4” min. gap around perimeter.

- ONLY remove the shims after ALL the gypsum board is completely screwed to ALL the drywall furring channels. Make sure every screw (floor to ceiling and wall to wall) is installed as required by the assembly design, in every layer of gypsum board before removing the shims at the floor. The shims are critical to ensure best results.

- Caulk around the entire perimeter of the gypsum board. Use fire and smoke rated acoustical sealant.

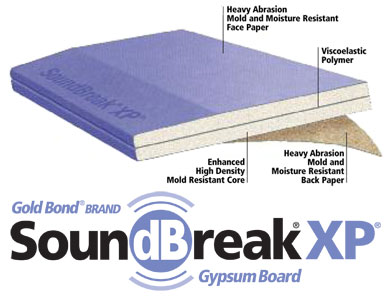

Wallboard Isolation - SoundBreak XP 5/8" Gypsum Board

SoundBreak® XP®

5/8"Gypsum Board with Sporgard™ has an acoustically enhanced, high density fire resistant Type X gypsum core encased in a heavy, abrasion and mold / mildew / moisture resistant, 100% recycled, National Gypsum PURPLE™ paper on both sides. Used in the construction of high rated STC wall assemblies, this 5/8" thick gypsum board consists

of a layer of viscoelastic damping polymer sandwiched between two pieces of high density mold resistant gypsum board, providing constrained layer damping.

SoundBreak® XP®

5/8"Gypsum Board with Sporgard™ has an acoustically enhanced, high density fire resistant Type X gypsum core encased in a heavy, abrasion and mold / mildew / moisture resistant, 100% recycled, National Gypsum PURPLE™ paper on both sides. Used in the construction of high rated STC wall assemblies, this 5/8" thick gypsum board consists

of a layer of viscoelastic damping polymer sandwiched between two pieces of high density mold resistant gypsum board, providing constrained layer damping.

Long edges of the panels are tapered. Tapered edges allow joints to be reinforced with ProForm® BRAND Joint Tape and concealed with ProForm® BRAND Ready Mix or ProForm® BRAND Quick Set Setting Compounds. For optimum mold and mildew performance, National Gypsum recommends ProForm® BRAND XP Ready Mix.

Basic Uses

For use as a single-layer application or as a component of multi-layered wall assemblies where sound transmission between rooms or dwelling units is a concern.

5/8"SoundBreak XP panels may be used where Type X gypsum panels are specified in some fire-rated wall and floor-ceiling assemblies (e.g., UL U300, U400, V400 and L500 series).

Advantages

- Resists the growth of mold per ASTM G 21 with a score of 0, the best possible score.

- Resists the growth of mold per ASTM D 3273 with a score of 10, the best possible score.

- Use of 5/8" SoundBreak XP Gypsum Board results in wall partitions with high rated STC values that are thinner than traditionally built high rated STC wall partitions, providing increased usable floor space.

- 5/8" SoundBreak XP Gypsum Board features a fire resistant Type X core and it is UL classified and approved for inclusion in specific UL fire-rated designs.

- Superior sound damping, cost-efficient material that is easily finished and decorated in the same manner as standard gypsum board.

- Heavy abrasion resistant paper and denser core provide greater resistance to surface abuse and indentation when tested in accordance with ASTM C 1629.

- All SoundBreak XP Gypsum Board designs were tested by an independent third-party acoustical laboratory using the full-scale ASTM E90 test procedure.

- SoundBreak XP Gypsum Board is installed like traditional gypsum board, offering a more reliable and less complicated solution than alternative methods requiring clips and/or channels.

- SoundBreak XP Gypsum Board can be cut by scoring deeply from both sides of the board before snapping, or with the use of a hand or electric saw.

- SoundBreak XP Gypsum Board is GREENGUARD Children & Schools Certified® for indoor air quality.

Approved for use on walls and ceilings.

Also, click here for our superior Sound-proof Doors